When I first began working with insulation materials, I was overwhelmed by the variety of options on the market — fiberglass, mineral wool, spray foam, and more. Each had its own promises: low cost, easy installation, good performance. But over time, I learned that not all insulation is created equal. The rise of Durfoam’s cross-linked polyethylene (PE) foam has transformed how architects, engineers, and builders think about insulation performance, durability, and sustainability. 🏗️

Traditional materials like fiberglass and mineral wool have been industry standards for decades. They work well in many applications but come with inherent limitations such as moisture absorption, dust release, and gradual degradation. In contrast, physically cross linked polyethylene foam and chemically cross linked polyethylene foam from Durfoam offer a modern alternative that combines long-term performance with cleaner, safer, and more sustainable features. 🌿

Let’s start with what makes cross-linked PE foam different. Unlike loose or fibrous insulation, polyethylene foam has a closed-cell structure. This means that each tiny air pocket is sealed off, preventing moisture from entering while providing uniform thermal resistance. Cross-linking — whether physical or chemical — strengthens the material at a molecular level, making it more durable, elastic, and resistant to compression. The result is insulation that doesn’t sag, crumble, or lose effectiveness over time. 💪

To better understand the differences, here’s a side-by-side comparison of traditional insulation types versus Durfoam’s cross-linked PE foam solutions:

| Feature | Fiberglass | Mineral Wool | Durfoam Cross-Linked PE Foam |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.040 | 0.035 | 0.032 🌡️ |

| Moisture Resistance | Low | Medium | Excellent 💧 |

| Durability | Moderate (sags over time) | High | Very High |

| Installation Safety | Can irritate skin and lungs | Requires protective gear | Non-toxic, dust-free 😌 |

| Environmental Impact | Not recyclable | Energy-intensive production | Recyclable, RoHS & REACH compliant 🌱 |

| Expected Lifespan | 10–15 years | 15–20 years | 30+ years |

As the table shows, Durfoam’s cross-linked foams outperform traditional materials in nearly every measurable category. What’s even more impressive is their versatility — they’re used in floors, walls, roofs, HVAC ducts, and even industrial applications. Unlike fiberglass, which can degrade when exposed to moisture or mechanical vibration, pe foam maintains its structure and performance no matter the conditions. ⚙️

Another major advantage is health and safety. Contractors who have made the switch to Durfoam report cleaner job sites, faster installations, and fewer worker complaints related to dust or irritation. The foam is odorless, non-toxic, and free from formaldehyde or other harmful chemicals — making it safer for both installers and building occupants. 🧱

From an environmental perspective, Durfoam stands out with its recyclable materials and eco-conscious production. The foams comply with RoHS and REACH regulations, contain no CFCs, and support sustainable building certifications like LEED and BREEAM. This makes them an excellent choice for green construction projects seeking to balance performance and responsibility. 🌎

However, no material is perfect. While Durfoam’s cross-linked foams offer many advantages, their upfront cost can be slightly higher than traditional insulation. That said, the lower maintenance requirements, longer lifespan, and energy savings typically offset this difference over time — turning the initial investment into significant long-term value. 💰

One building consultant I spoke with described it best: “With fiberglass, you save on day one but pay for it later in energy bills and repairs. With Durfoam, you invest once and forget about it.” That perfectly sums up the true cost-benefit perspective of modern insulation technology. 🏢

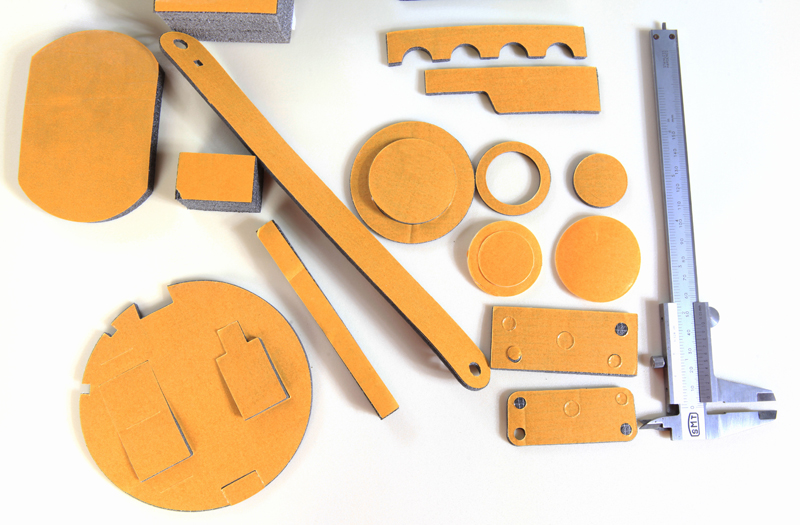

All of these benefits stem from the same place — Durfoam’s meticulous production process. Each batch of foam is tested for density, cell uniformity, and mechanical strength to ensure it performs flawlessly across diverse climates and applications. Here’s where that precision and commitment to quality come to life 👇

And to see how Durfoam’s cross-linked foams are made and tested for real-world conditions, check out this behind-the-scenes video 👇

In conclusion, while traditional insulation materials still have their place, the advantages of Durfoam’s cross-linked PE foam are hard to ignore. Combining thermal efficiency, moisture resistance, durability, and eco-friendliness, it represents the next generation of insulation technology — one that delivers comfort today and sustainability for decades to come. 🌟

You should also read these…

- godwig.com – why am i restricted from tiktok dms

- spyfrogs.com – haarverlangerungen fur feines haar welche methode

- spyfrogs.com – the hidden risks of x spaces could you be getting

- huesly.com – churches mosques synagogues and which communities

- spyfrogs.com – industrial packaging with durfoam protecting goods

- surgeblog.com – tiktok compatibility issues ios vs android

- soturk.com – tiktok trend sounds not loading

- noepic.com – comment restrictions on tiktok child accounts

- surgeblog.com – custom workbenches designed for maximum productivi

- toojet.com – say goodbye to dinner indecision flavor adventures